Sheet Steel Fabrication

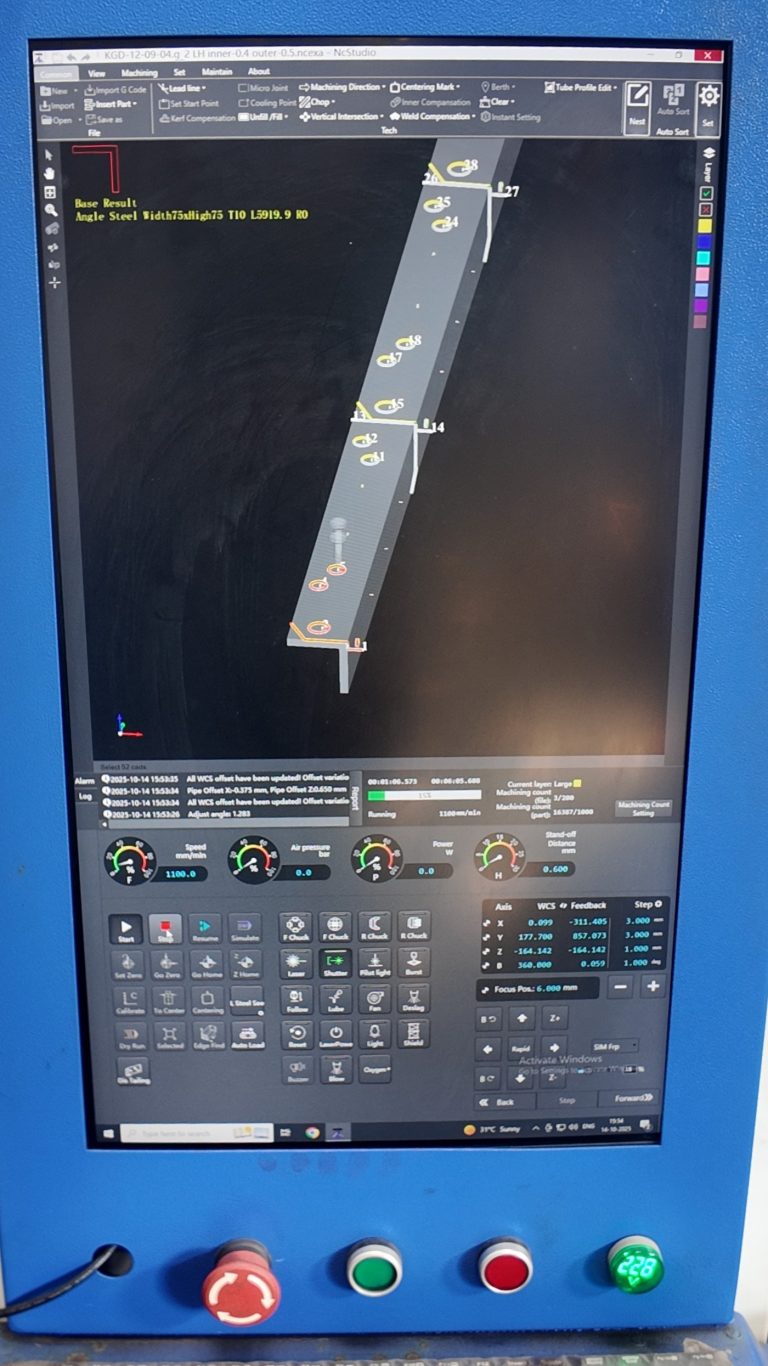

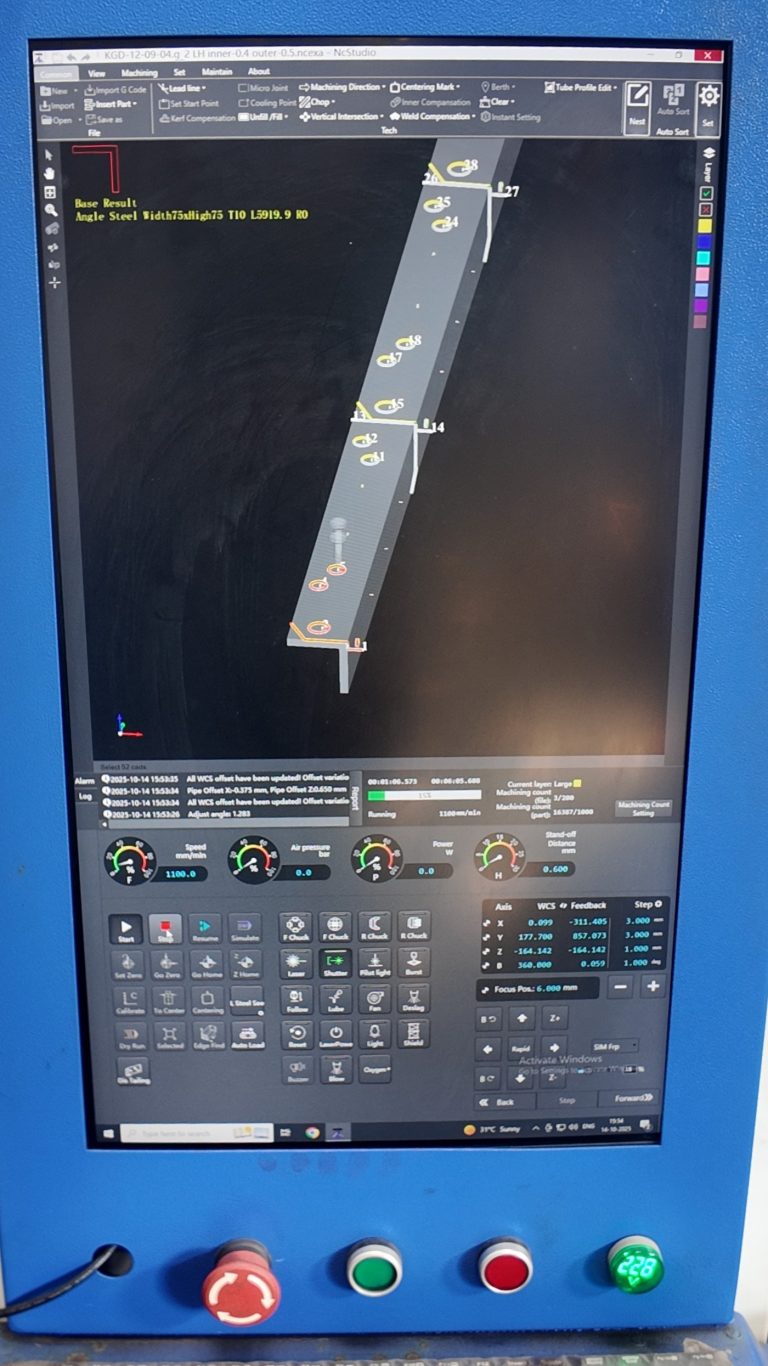

At Rishi Laser, we specialize in delivering high-quality Sheet Steel Fabrication and assembled products through advanced machinery, modern software, and skilled teams. Our engineers use AutoCAD, Radan, and other tools to design 3D models, prepare flat patterns, and create CNC programs for cutting, bending, and punching. In production, components are manufactured using high-accuracy CNC laser cutting machines, press brakes, and turret punch presses to maintain consistent shape and reliable dimensions.

Our fabrication units handle simple to complex assemblies with MIG, MAG, TIG, CO₂, gas, and projection welding, supported by modular fixtures and robotic welding for repeatability and strength. Every assembly is prepared for finishing through shot blasting, seven-tank treatment, or liquid dipping, followed by powder coating, epoxy painting, or zinc plating.

With Lean Manufacturing practices across all facilities and a strong multi-location setup, Rishi Laser ensures dependable fabrication, faster turnaround, and consistent quality for engineering and industrial applications.

At Rishi Laser, we specialize in delivering high-quality Sheet Steel Fabrication and assembled products through advanced machinery, modern software, and skilled teams. Our engineers use AutoCAD, Radan, and other tools to design 3D models, prepare flat patterns, and create CNC programs for cutting, bending, and punching. In production, components are manufactured using high-accuracy CNC laser cutting machines, press brakes, and turret punch presses to maintain consistent shape and reliable dimensions.

Our fabrication units handle simple to complex assemblies with MIG, MAG, TIG, CO₂, gas, and projection welding, supported by modular fixtures and robotic welding for repeatability and strength. Every assembly is prepared for finishing through shot blasting, seven-tank treatment, or liquid dipping, followed by powder coating, epoxy painting, or zinc plating.

With Lean Manufacturing practices across all facilities and a strong multi-location setup, Rishi Laser ensures dependable fabrication, faster turnaround, and consistent quality for engineering and industrial applications.

Industries we Served

Automotive

Earthmoving Equipment

Railways

Power Plant

Electrical Switchgear

Aerospace & Defense

Chemical & Food Processing

Telecommunication

Textile & General Engineering

Automotive

Earthmoving Equipment

Railways

Power Plant

Electrical Switchgear

Aerospace & Defense

Chemical & Food Processing

Telecommunication

Textile & General Engineering