Manufacturing Solutions

Rishi Laser’s Manufacturing Solutions represent a unified approach to Modern Manufacturing, combining Metal Fabrication expertise with automation and digital platforms. With dedicated divisions including RL Robotics, 247 Cut Bend, and RL Bend, we deliver flexible, efficient, and future-ready manufacturing capabilities.

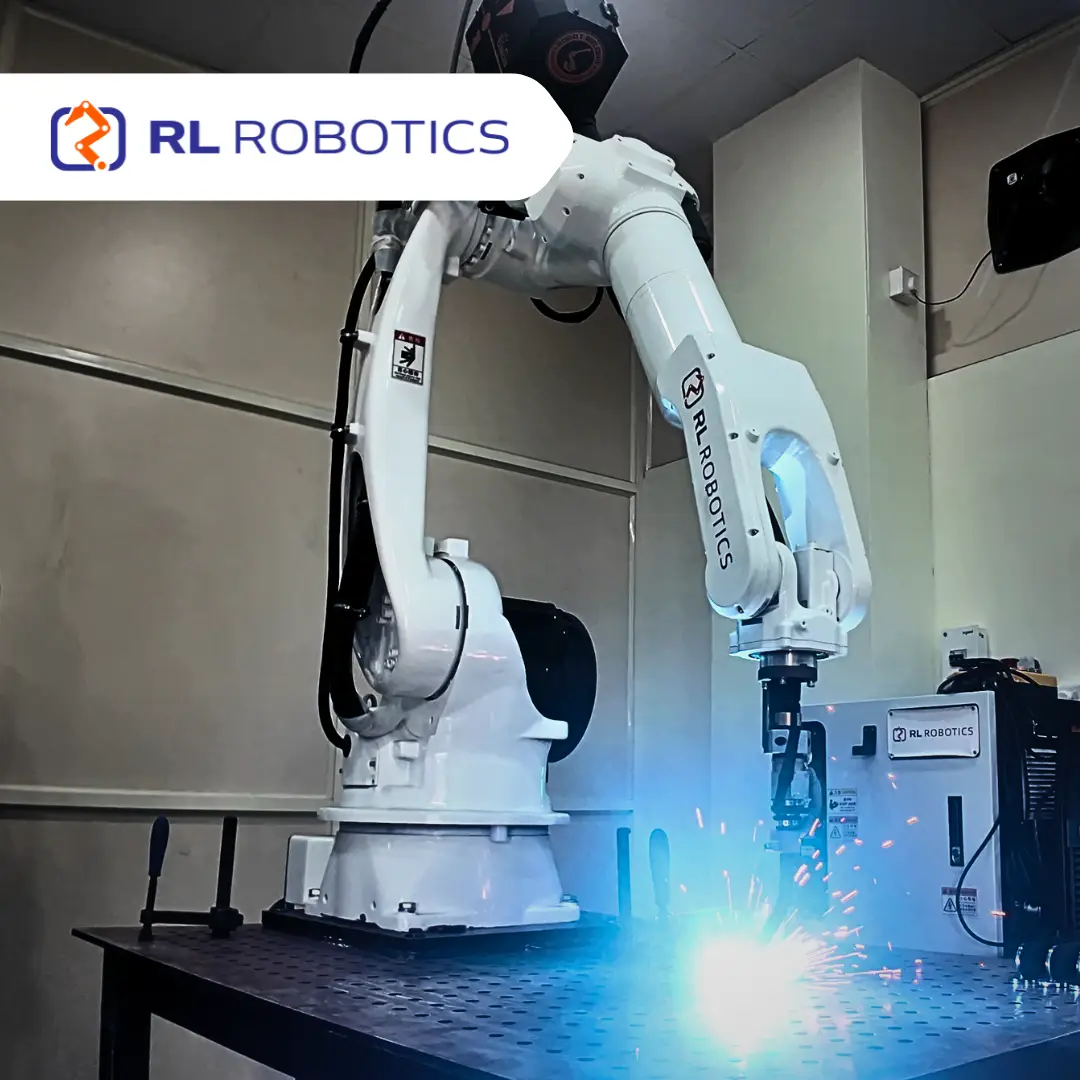

RL Robotics delivers intelligent welding automation solutions that make metal fabrication faster, safer, and more consistent. Our robotic welding systems minimize manual dependency while ensuring clean, accurate, and repeatable weld quality helping manufacturers improve productivity and process reliability.

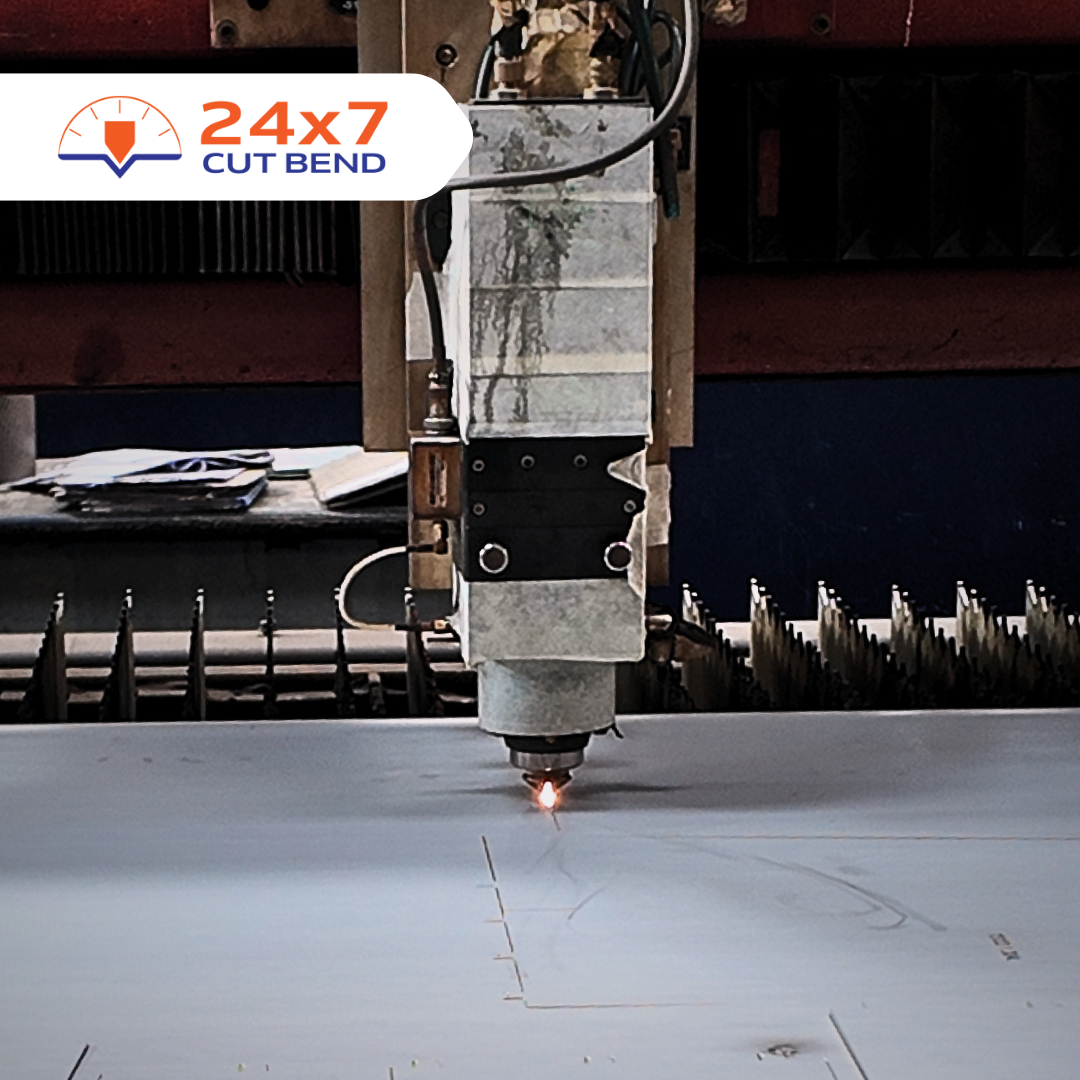

247 Cut Bend delivers fast, precise, and reliable sheet metal manufacturing through an integrated combination of laser cutting, CNC bending, and fabrication. Built on a 24/7 production mindset, our digital-first approach enables quick turnaround times, consistent quality, and dependable output for engineering-driven requirements.

RL Bend offers advanced Press Brake bending solutions designed for precise, repeatable, and efficient sheet metal forming. Our CNC press brakes enable accurate bending of mild steel, stainless steel, and aluminum, supporting a wide range of applications from panels and enclosures to complex structural components while ensuring consistency, productivity, and process reliability.

- Technology Options - Hydraulic, Servo-Hydraulic & Fully Electric Press Brakes

- High Accuracy - CNC control with automatic bend calculation & deflection compensation

- Energy Efficient - Servo & electric models reduce power consumption & noise

- Wide Capacity Range - Solutions for light to heavy-duty bending requirements

- Fast & Consistent - Optimized cycle times for higher productivity

- Automation Ready - Designed for modern, Industry 4.0 environments

H Series

• Heavy-duty, stress relieved welded frame.

• High precision Electro Hydraulic control.

• Stable synchronization & repeatable accuracy.

• 6 + 1 axis back gauge with automatic crowning.

• HACO 60 CNC for advanced bending performance.

SH Series

• Equipped with Servo Motor as main motor. The motor only operates when the downward stroke is in

operation, which reduces energy consumption.

• Up to 30% reduced noise levels.

• Lower oil temperature & zero overflow.

• Longer hydraulic life, reduced maintenance.

• High-efficiency, stable bending output.

E Series

• Fully electric, oil free operation

• High accuracy with clean, quiet performance

• Low power consumption & eco-friendly

• Minimal maintenance requirements

• Advanced servo-electric precision bending

Industries we Served

Automotive

Earthmoving Equipment

Railways

Power Plant

Electrical Switchgear

Aerospace & Defense

Chemical & Food Processing

Telecommunication

Textile & General Engineering

Automotive

Earthmoving Equipment

Railways

Power Plant

Electrical Switchgear

Aerospace & Defense

Chemical & Food Processing

Telecommunication

Textile & General Engineering